When it comes to lighting in harsh environments, such as industrial facilities, parking garages, and food processing plants, traditional lighting fixtures often struggle to withstand the tough conditions. However, with the advancement of technology, easy-install vapor tight retrofit lights have emerged as a game-changer in upgrading harsh environment lighting. In this article, we will delve into the benefits and installation process of these innovative lighting solutions.

The Advantages of Upgrading to Easy-Install Vapor Tight Retrofit Lights

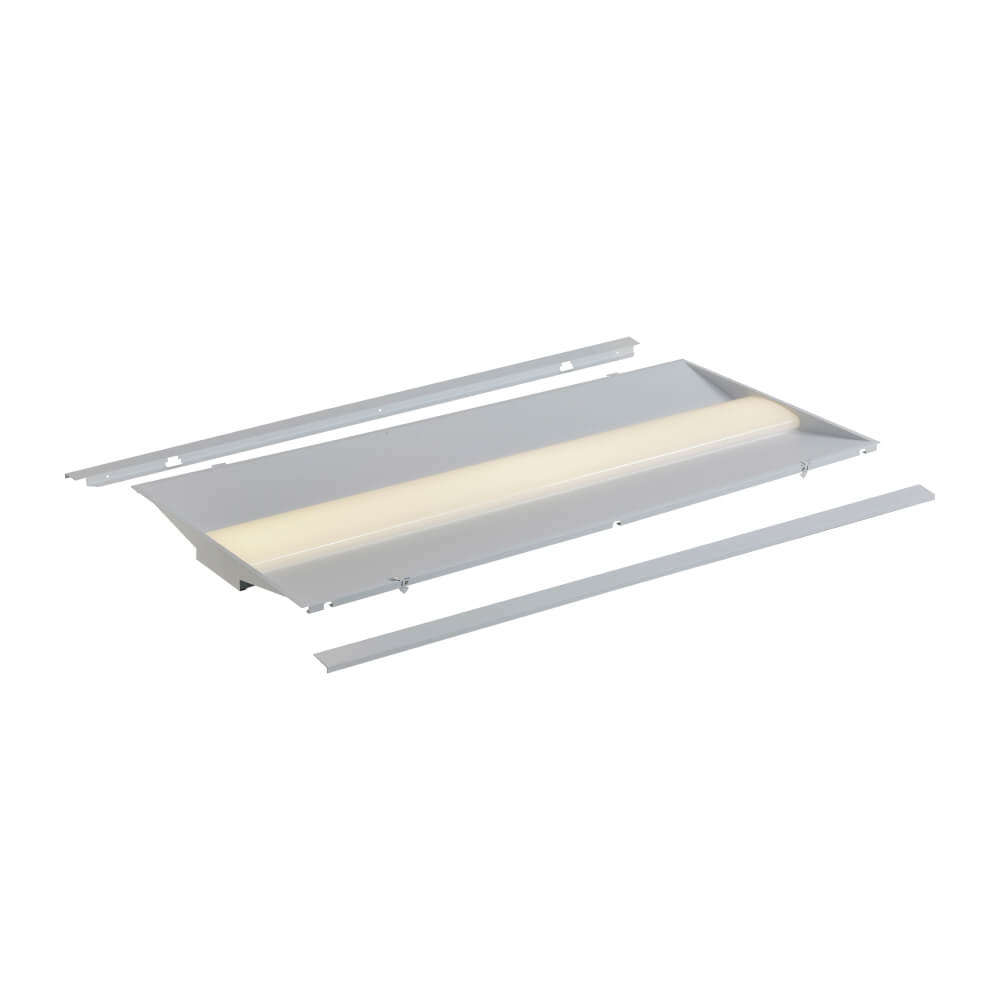

Upgrade Your Harsh Environment Lighting with Easy-Install Vapor Tight Retrofit Lights offer a multitude of benefits that make them a superior choice for harsh environments. These lights are specifically designed to withstand moisture, dust, and corrosion, making them ideal for use in areas where traditional lighting may fail. Additionally, they are energy-efficient, providing significant cost savings in the long run. The durability and longevity of these lights also reduce maintenance and replacement costs, further adding to their appeal.

Installation Process of Easy-Install Vapor Tight Retrofit Lights

One of the key advantages of Upgrade Your Harsh Environment Lighting with Easy-Install Vapor Tight Retrofit Lights is their ease of installation. Unlike traditional lighting fixtures that may require complex wiring and mounting procedures, these retrofit lights are designed for quick and hassle-free installation. With their innovative design, they can be easily retrofitted into existing fixtures, eliminating the need for extensive modifications to the lighting infrastructure.

Key Considerations for Installation

Before embarking on the installation of Upgrade Your Harsh Environment Lighting with Easy-Install Vapor Tight Retrofit Lights, it is essential to assess the specific requirements of the environment. Factors such as the mounting location, wiring compatibility, and environmental conditions should be carefully evaluated to ensure a seamless installation process. Additionally, it is advisable to seek professional assistance to guarantee the optimal placement and configuration of the retrofit lights.

Applications of Upgrade Your Harsh Environment Lighting with Easy-Install Vapor Tight Retrofit Lights

Upgrade Your Harsh Environment Lighting with Easy-Install Vapor Tight Retrofit Lights are versatile and find applications in a wide range of harsh environments. From manufacturing facilities and warehouses to outdoor walkways and transit stations, these lights offer reliable illumination in challenging conditions. Their ability to withstand moisture and contaminants makes them suitable for use in food processing facilities, car washes, and other demanding settings where traditional lighting may falter.

Case Study: Industrial Facility Lighting Upgrade

An industrial facility facing frequent lighting failures and high maintenance costs opted to upgrade its harsh environment lighting with easy-install vapor tight retrofit lights. The installation not only resolved the reliability issues but also resulted in substantial energy savings. The durability of the retrofit lights proved to be a cost-effective solution, reducing the need for frequent replacements and maintenance, thereby enhancing the overall operational efficiency of the facility.

In conclusion, Upgrade Your Harsh Environment Lighting with Easy-Install Vapor Tight Retrofit Lights offer a compelling solution for upgrading lighting in challenging environments. Their durability, energy efficiency, and ease of installation make them a preferred choice for businesses seeking reliable and cost-effective lighting solutions. By embracing these innovative lights, organizations can enhance safety, reduce operational costs, and improve the overall quality of lighting in harsh environments.